PFAS in Clothing: How the Fashion Industry is Moving Toward Safer, More Sustainable Alternatives

What Are PFAS and Why Are They Used in Textiles?

PFAS (per- and polyfluoroalkyl substances), often called “forever chemicals”, are widely used in clothing and textiles for water and stain resistance. Often found in raincoats, outdoor gear, activewear, uniforms, and even household textiles, PFAS in clothing can help fabrics repel moisture, oil, and dirt.

While these chemicals enhance performance, their impact on human health and the environment is alarming. PFAS persist in the environment indefinitely, contaminating drinking water, soil, and wildlife. Studies link PFAS exposure to immune system suppression, hormonal disruptions, fertility issues, and increased cancer risk. As a result, regulators and consumers alike are pushing for PFAS-free alternatives in fashion and textiles.

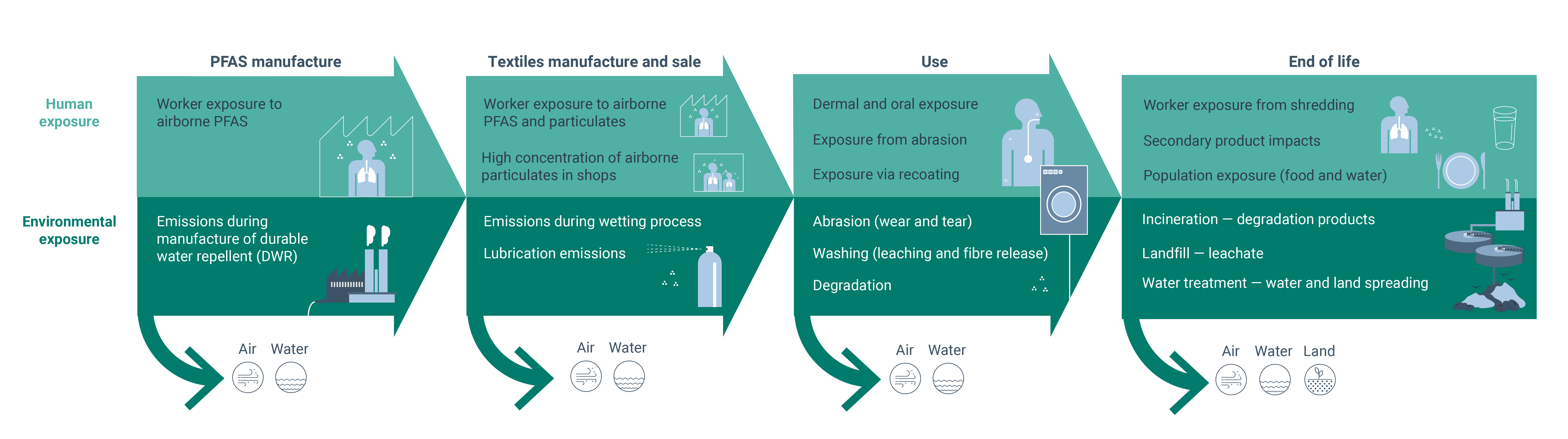

The Lifecycle of PFAS in Textiles: From Production to Pollution

Source: European Environment Agency (EEA). Used under the Creative Commons Attribution License.

According to the European Environment Agency (EEA), PFAS enter the environment at every stage of textile production, from manufacturing to disposal.

Regulations Are Driving PFAS Out of Fashion

As the dangers of PFAS become more widely recognized, governments worldwide are enacting stricter regulations to limit or ban their use in textiles and apparel. These laws aim to protect public health and reduce environmental contamination, forcing brands and manufacturers to find safer alternatives.

For the fashion industry, staying compliant isn’t just about avoiding fines or legal consequences—it’s about maintaining consumer trust and meeting sustainability goals. Consumers are more aware than ever of the risks associated with PFAS, and many are actively seeking out PFAS-free clothing options.

To keep up with the rapidly changing regulatory landscape, brands must eliminate PFAS from their supply chains and adopt certified, sustainable alternatives. Here are some of the most significant PFAS regulations affecting the textile industry today:

Key PFAS Bans Affecting the Textile Industry

United States:

- California (AB 1817): Bans intentionally added PFAS in textiles starting January 2025.

- New York: Prohibits apparel with PFAS, except outdoor gear for severe wet conditions until 2028.

- Colorado: Phasing out PFAS in outdoor clothing, requiring disclosure labels until a full ban in 2028.

Europe:

- European Union: Some PFAS groups, namely PFCA and PFHxA, are already banned from the use in consumer textiles.

- The European Chemicals Agency (ECHA) is advocating a universal PFAS ban under the REACH Regulation

s, potentially influencing restrictions worldwide.

- France (Law No. 2025-188): Bans PFAS in textiles, footwear and waterproofing agents for consumer use from January 2026.

- Denmark: Has announced to prohibit importing or selling PFAS containing clothing and footwear to consumers for private use from July 2026.

As PFAS-free textiles become the industry standard, brands must adapt quickly to remain compliant and meet consumer expectations.

Challenges in Phasing Out PFAS in Clothing

Textile manufacturers and brands face several obstacles in eliminating PFAS from clothing:

- Performance issues: Alternative treatments must match PFAS in durability, water repellency, and stain resistance.

- Compliance complexity: Regulations vary by region, making it difficult for global brands to navigate evolving standards.

- Supply chain transparency: Many manufacturers lack visibility into the chemicals used in their supply chain.

- Consumer trust: Increasing awareness of PFAS risks means brands must prove their sustainability claims with independent verification.

PFAS-Free Clothing: What Are the Alternatives?

Eliminating PFAS from textiles is a major challenge for brands and manufacturers that have relied on these chemicals for decades. However, advances in material science and chemistry are providing safer, high-performance alternatives that meet both regulatory requirements and consumer expectations.

1. Water-Based and Silicone-Based Repellents

One of the most promising PFAS-free alternatives comes from water-based and silicone-based finishes, which provide effective water repellency with less severe harmful effects.

- Water-based repellents use hydrophobic (water-repelling) treatments that form a barrier on the fabric.

- Silicone-based technologies create a flexible, durable coating that repels moisture while allowing fabric breathability.

These alternatives are already being adopted in outdoor gear, rainwear, and sportswear, offering a sustainable solution without sacrificing performance.

2. Bio-Based and Plant-Derived Coatings

As the fashion industry shifts toward natural and renewable materials, many brands are exploring bio-based alternatives to PFAS.

- Wax-based coatings made from beeswax or soy wax provide natural water resistance.

- Plant-derived polymers offer stain resistance while remaining biodegradable.

- Chitosan-based treatments (derived from crustacean shells) have antimicrobial and water-repellent properties.

These natural solutions align with sustainability trends and appeal to eco-conscious consumers looking for PFAS-free clothing options.

3. Tightly Woven Fabrics for Natural Water Resistance

Instead of relying on chemical treatments, some brands are turning to textile engineering to create naturally water-resistant fabrics.

- Densely woven materials like tightly spun polyester, nylon, or organic cotton provide water repellency without coatings.

- Wool and waxed cotton naturally resist moisture and stains, making them ideal alternatives for outerwear and accessories.

- Layering techniques can enhance durability, such as laminated or multi-layered fabrics that repel water without chemical additives.

By leveraging these structural innovations, brands can reduce reliance on chemical treatments altogether.

4. Advanced Polymer Coatings (PFAS-Free DWR Technologies)

Durable water repellent (DWR) coatings have traditionally relied on PFAS, but new PFAS-free versions are emerging.

- Hydrocarbon-based DWRs mimic the performance of PFAS with the option of being biodegradable.

- Hyperbranched polymers create a multi-layered barrier against moisture and stains.

- Fluorine-free nanocoatings enhance fabric durability while maintaining breathability.

These next-gen textile technologies allow brands to maintain functionality while involving a potential for reduced toxicity.

5. Supercritical CO₂ Dyeing & Finishing

Innovative CO₂-based fabric treatments eliminate the need for PFAS, water, and harmful solvents.

- Supercritical CO₂ dyeing infuses fabrics with color and repellency without using water or toxic chemicals.

- Plasma treatments modify fabric surfaces at a microscopic level to create natural water-repelling properties.

These high-tech alternatives not only reduce chemical pollution but also cut water and energy consumption, aligning with sustainable production goals.

6. Emerging Sustainable Coatings & Innovations

The textile industry is rapidly investing in sustainable chemistry, and new solutions are constantly being suggested.

- Graphene-based coatings offer extreme durability and water repellency while promising a minimal environmental footprint.

- Protein-based coatings (inspired by nature, like lotus leaf structures) repel moisture without synthetic chemicals.

- Recycled material treatments may provide sustainable, closed-loop solutions that maintain performance while reducing waste.

As research and development continue, PFAS-free textiles will only become more effective and widely available.

How Brands Are Transitioning to PFAS-Free Fashion

Many leading brands and bluesign System Partners are already adopting these alternatives in their products:

- Patagonia & The North Face: Transitioning to bio-based waterproof coatings.

- Adidas: Investing in fluorine-free DWR for athletic apparel.

- Jack Wolfskin: Having replaced PFAS-based DWR by fluorine-free membranes and coatings for outdoor clothing.

Bluesign is at the forefront of this transformation, helping brands phase out PFAS and adopt safer, sustainable solutions without compromising quality.

How bluesign Is Leading the PFAS-Free Movement

As a global leader in sustainable textile solutions, bluesign has been committed to eliminating harmful chemicals from textiles since 2000.

bluesign’s PFAS Phase-Out Timeline

2015: bluesign banned long-chain PFAS (C8 chemistry) in all bluesign-approved products.

2022: New PFAS-containing chemicals were prohibited from bluesign FINDER, the database of approved chemical products.

2023: All existing PFAS chemicals were removed from bluesign FINDER and banned from certification.

2024: Registration of new bluesign product materials treated with PFAS-containing chemicals is no longer possible.

January 2025: bluesign will fully eliminate short-chain PFAS (C6 chemistry) from bluesign-approved products, with limited exemptions for essential uses (e.g., personal protective equipment).

January 2026: All remaining substance-related exemptions will be removed from bluesign product certification.

What This Means for Consumers and Brands

By removing PFAS from textiles, bluesign helps ensure that:

- Manufacturers and brands remain compliant with evolving PFAS regulations.

- Consumers have safer, PFAS-free clothing options without compromising performance.

- The textile industry moves toward a cleaner, more sustainable future.

How bluesign Helps Brands and Consumers Transition Away from PFAS

Bluesign plays a crucial role in helping brands eliminate dangerous PFAS from their supply chains by providing a transparent, science-based approach to chemical management.

Through its certification system, bluesign works directly with textile manufacturers to identify and remove harmful substances at the source, ensuring that materials meet the highest standards for environmental and consumer safety.

By phasing out PFAS-containing chemicals and promoting safer alternatives, bluesign helps brands comply with evolving regulations while maintaining product performance.

For consumers, the bluesign product label serves as a trusted guide to PFAS-free clothing, allowing them to make informed choices that align with their sustainability values.

The Future of PFAS-Free Fashion

Consumers are increasingly demanding non-toxic, sustainable fashion, and the industry is responding. Leading brands are partnering with certification organizations like bluesign to verify their PFAS-free claims and meet the growing demand for eco-friendly textiles.

By choosing bluesign-approved textiles, manufacturers, retailers, and consumers can ensure safety, sustainability, and transparency—helping to eliminate harmful PFAS from fashion for good.

Contact us today to learn more about how bluesign helps the textile industry eliminate PFAS from their products.

Reviewed by Daniel Waterkamp, Ph.D.

Head of bluesign Academy

This article was reviewed by Daniel Waterkamp, a chemical engineer and sustainability professional with a PhD in process engineering. As Head of bluesign Academy, Daniel oversees chemical compliance for international brands and helps develop safer, sustainable solutions for the textile industry. His expertise ensures the accuracy and relevance of the information presented.